Implementation of DTL Monitoring for Municipal Services Department in Baborów

At the beginning of 2018 Dataland Ltd. had set a new task, the aim of which was to develop a telemetry system for water supply infrastructure located in three communes. After three months, the pilot project was implemented in the water treatment station Sucha Psina. It was the first monitored facility and this was the beginning of the new DTL Monitoring project.

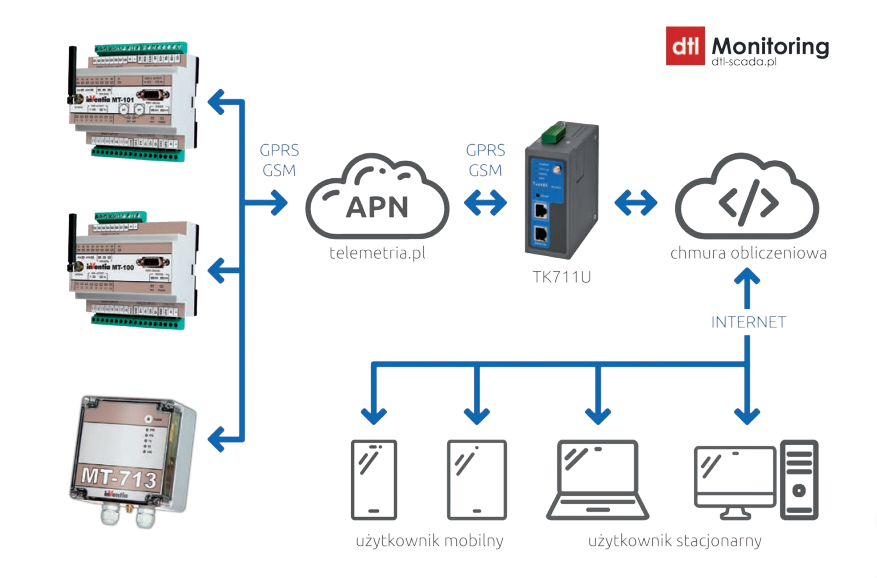

The company Dataland Ltd. has been a software producer for many years, with particular reference on solutions based on mobile applications. Yes, and they did it again this time. We wanted to create a system that will notify the technical infrastructure staff as soon as possible about the event of failure or anomalies in the work of the facilities covered by the monitoring. Currently, solutions based on the operation of mobile applications and data storage in the cloud is the part of a fast-growing segment of the IT market. DTL Monitoring is an IT system designed for the supervision, control, and acquisition of data from technical facilities. The user of the system has access to data from the level of a dedicated application for mobile devices (smartphone, tablet) and a web browser via the website.

The scope of the DTL Monitoring system includes:

- Displaying current telemetry data from technical facilities,

- Access to archived data and their processing for analytical purposes,

- Notification system for selected changes in a specific technological process

- Alert system for notifying about emergency conditions of operating devices that may lead to disruption or interruption of the technological process,

- Application of automatic procedures to inform about discrepancies in the parameters of monitored processes (trend analysis),

- Automatic generation of reports within the set time periods regarding the balance of a given facility,

- Remote control of devices.

Why did we choose a solution based on a mobile application?

It is hard to disagree that nowadays most of us almost do not part with their smartphone. We are available on-line practically 24 hours a day, we search for desired information on the web and share our content with others. The use of mobile technology in relation to the process of monitoring technical facilities is an undoubted advantage for the service staff who needs to be quickly notified about the failure regardless the time of day or where they are at a given moment. This does not mean, however, that we give up a typical computer monitor screen for a dispatcher or a manager of a given infrastructure, which is an essential element of any SCADA system. We, however, give it a more analytical than operational character, which in the case of water supply systems seems to be justified.

A small company can also have telemetry!

„Telemetry is expensive and only large plants can afford it.” Such an opinion can often be heard in smaller waterworks that manage the network in a small municipality somewhere in the province. Our implementation shows that it does not have to be that way! Together with the board of ZUK Baborów, we managed to design an advanced telemetry system optimally suited to the user’s needs, develop a financing plan, provide the necessary equipment and finally run a system based on modern information technologies.

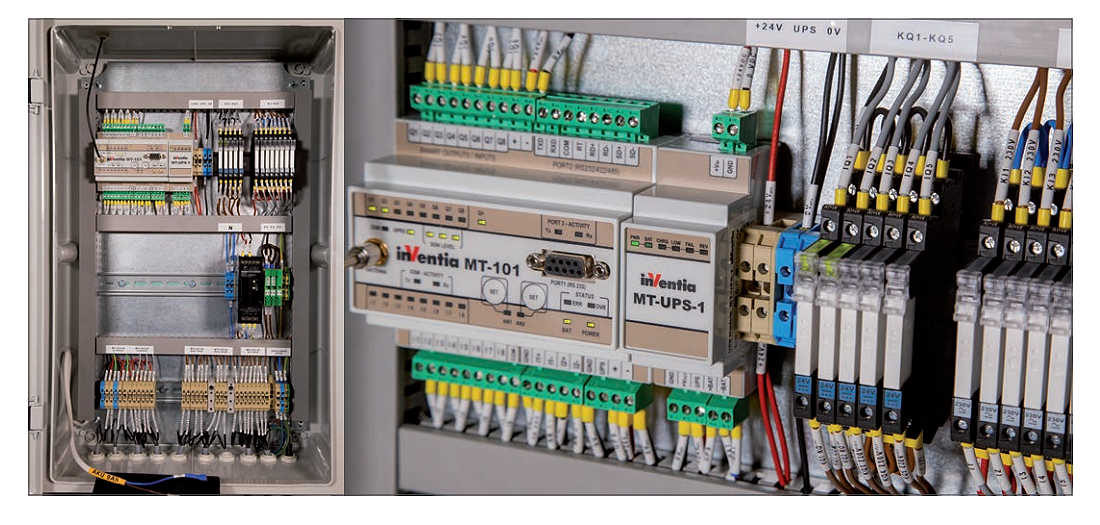

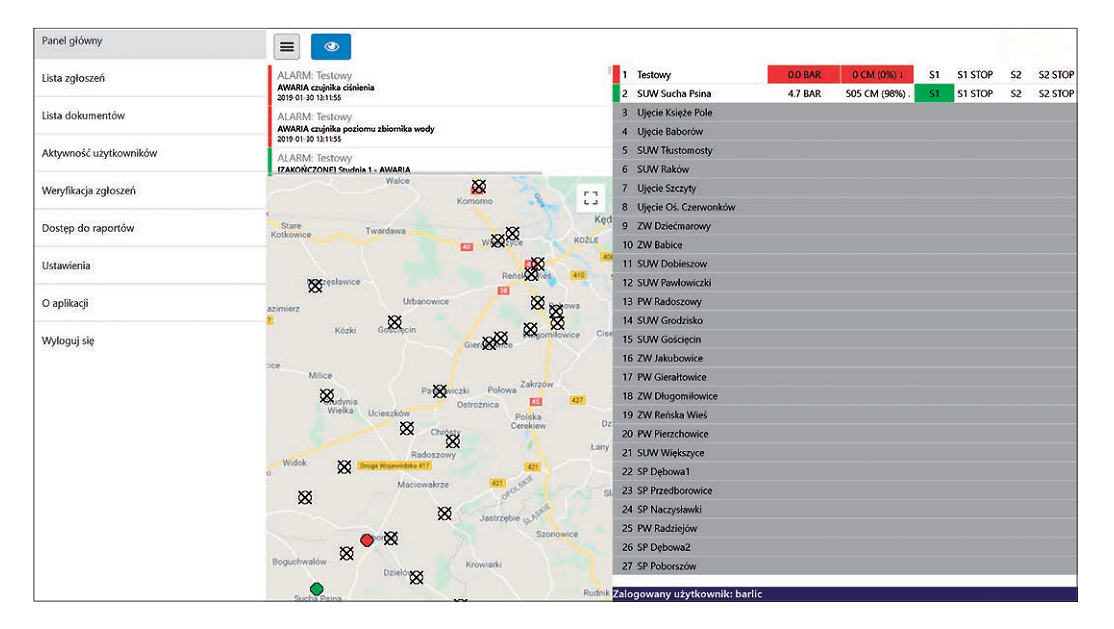

We started the construction of the entire telemetry system at the beginning of 2019. The first stage of implementation includes 26 important points of water supply infrastructure distributed across three communes administered by ZUK Baborów. These are mainly water intakes, water treatment stations, drinking water retention reservoirs and measuring wells on the main water mains. While selecting telemetry devices that work in the field, we wanted to be sure that these devices would be technologically advanced with high functionality. It was also important to have well-developed documentation, warranty and technical support from the manufacturer. Our cooperation with InVentia has been established here. We bet on a Polish manufacturer with many years of experience in the market. The devices have been optimally selected for the needs of a given point in the water supply network. The MT-101 telemetry modules were installed mainly on larger water supply stations. Their task is to transfer the current station operation parameters and supervise the operation of devices. The possibility of using a large program capacity of the module makes the MT-101 a full-size PLC, which can be used to optimize the station’s operation. In the future, this will allow for modernization of station automation devices, where the majority of control functions will be taken over by the InVentia telemetry module. Smaller stations have been equipped with MT-100 modules acting like a typical supervisor monitoring the operation of devices. For the purposes of this implementation, a universal telemetry cabinet has been developed that allows connection of all monitored devices to telemetric modules. We have predicted the space for expanding the system with further modules, e.g. EX-101 or other devices communicating via the serial port with the MT-101 module.

Seventeen telemetry cabinets have been installed at all water supply stations with continuous power supply from the power mains.

Other points covered by the monitoring are the places that required the use of battery-powered modules. In this case, the MT-713v2 HC HV telemetry module was used, which was put into the measuring wells and some retention reservoirs of drinking water. The version of the HC module with an increased battery capacity guarantees longer module life, and the optional HV extension

allowed us to adapt to the pressure transducers and hydrostatic probes installed on these objects.

Hierarchical notification structure

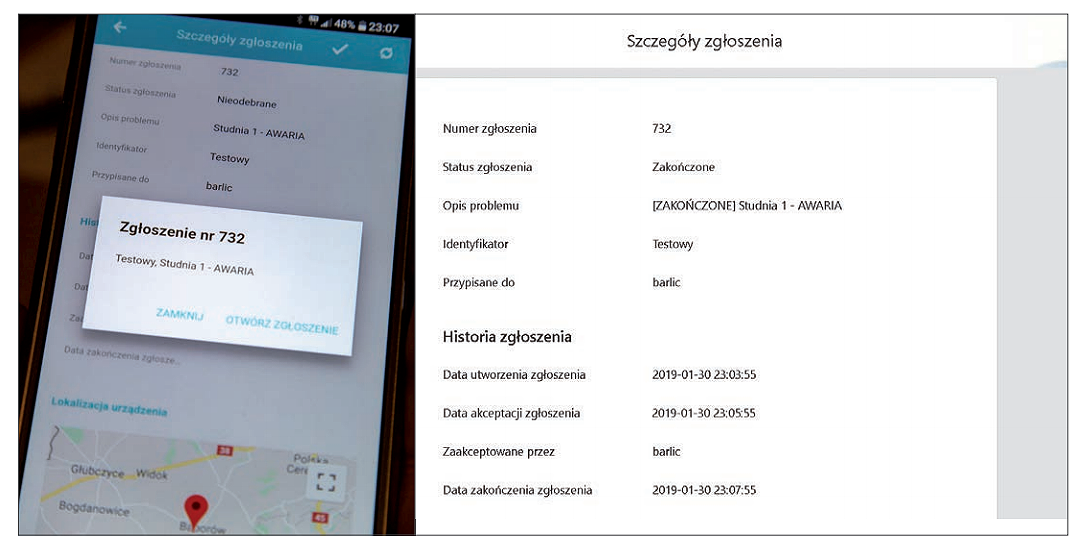

Each user of the DTL Monitoring IT system is identified by a unique username and password assigned to him. Each user has the assigned monitored points and a range of privileges in the system. The system allows sending notifications to all users or to selected groups or individuals. Each alarm generates sending information to the users assigned to it, and the recipient must confirm receiving messages in the application. Event information can be sent to all assigned people in parallel or according to a specific key to individual users of the system. For example, information about an event at a given water treatment station goes first to the maintenance technician responsible for this object. This person, should confirm the received information in the application and take appropriate action in the facility. If at the given time the system does not receive confirmation of message receipt, it will alert the next user, e.g. the water and sewage emergency or the manager. Such a hierarchical notification system transforms into a better organization of work in the company.

Functionality for the explorer

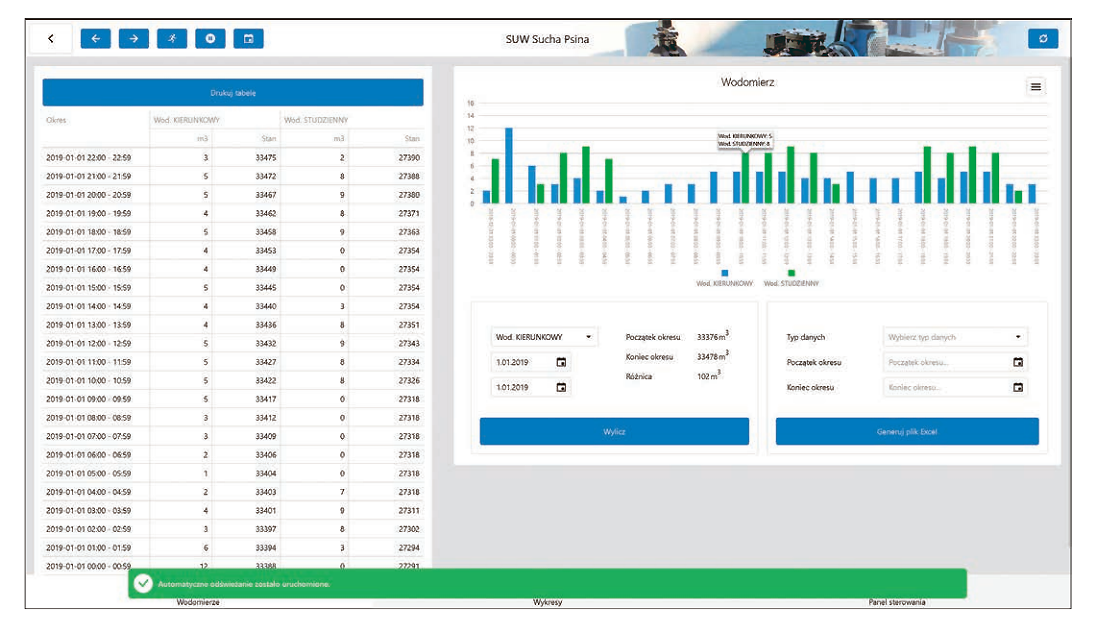

Notifications of emergencies are only part of the tasks that the DTL Monitoring system performs. Wide range of possibilities of analysis and processing of collected data should be of interest to the insightful manager of the water supply infrastructure. The system implemented for ZUK Baborów uses both the potential of InVentia telemetry modules as well as the work with a database. Significant data collected by telemetry modules MT-101 and MT-100 are put off in their internal registers and then sent to the system. This allows you to automatically generate the monthly reports for each monitored point, containing all relevant data relating to the work efficiency of the object.

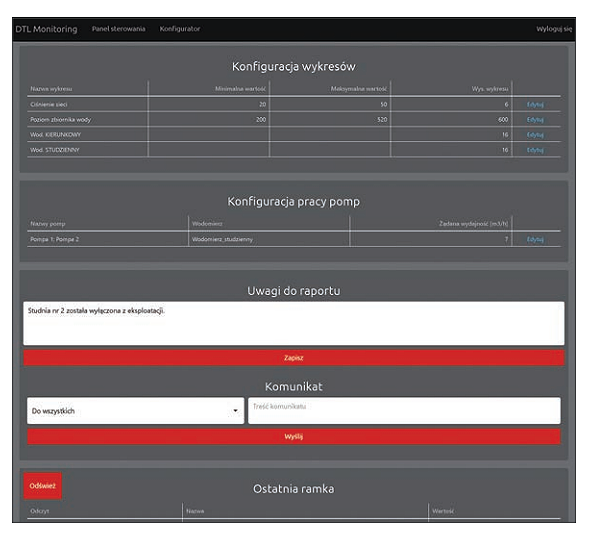

In addition to the algorithms implemented in telemetry modules, tools for analyzing data retrieved from the database have been created. In this way, for example, night consumption of water is analyzed in a given area of the water mains supply. Such analysis is helpful in quickly detecting leakages on the network. The detected anomaly is signaled by an appropriate notification sent to the dispatcher. Analyzes of water level trends in retention reservoirs help in assessing the efficiency of deep-well pumps. The user can download specific data to a spreadsheet, where he can analyze it in any way. Another feature of the DTL Monitoring system is the control panel. The user having access to it, after logging in, has the possibility of remote control of devices connected to telemetry modules on monitored facilities. We can, for example, switch off a given deepwell pump or change the setting of the gate valves with an electric drive. The use of remote control capabilities of InVentia telemetry modules allows you to significantly reduce the travel costs of service personnel to a given water supply facility.

Next stages of implementation

The great functionality of InVentia telemetry modules allows for extensive expansion of the entire telemetric system. Water supply network management also means care for water quality. In addition to monitoring the work of typical devices, such as deep-well pumps or hydrophore sets, we want to be able to control the basic physical and chemical parameters of water. Telemetry modules MT-101, enable downloading data from external devices equipped with communication port RS232/422/485. The next year will be for the Dataland staff the year of full use of this functionality. InVentia telemetry modules, water quality control devices and the DTL Monitoring IT system should constitute an indispensable tool for the daily work of the water supply infrastructure manager.