User software tools

CODESYS®

CODESYS® is advanced, fully free software used to program selected telemetry controllers in the Inventia range. It provides intuitive and efficient tools for developing internal control applications, combining advanced technical features and easy operation. It provides access to a variety of functions, including: text editor, diagnostics, device simulator. It is a popular programming system of choice for many different manufacturers, and is constantly being developed.

The Codesys editor provides the ability to create programmes based on all the standard languages specified in PLC standards: Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Instruction List (IL), Sequential Function Chart (SFC). In addition, it enriches them with the C language, allowing the creation of even more advanced programmes. Importantly, there is the freedom to use them according to the programmer’s preference within a single project.

Debugging functionality is available to verify the operation of the written code directly on the telemetry controller or on a virtual device, a simulator, which in turn provides testing of the operation of the programme code without the need for a physical telemetry controller.

CODESYS advantages:

- IEC 61131-3 compliant – available languages include ST, LD, FBD, SFC, as well as C

- Extensive diagnostic tools

- Extensibility of individual functionalities by adding libraries

- Ease of code transfer between different programs

- Built-in visualisation tool with a ready-made set of elements for process monitoring and control

- Ability to define your own functions and function blocks

- Documentation tool

What does MT gain by using CODESYS software?

- Create programmes using the most popular PLC programming methods in automation, such as Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), or Sequential Function Chart (SFC)

- The ability to use several programming languages within a single project allows the best one to be selected for the task at hand

- Possibility to create several threads

- Access to a rich set of ready-made libraries that extend the functionality of the environment. This speeds up the programming process and facilitates the development of advanced applications

- Ability to define your own functions and function blocks

- Compliance with the IEC 61131-3 standard, which is widely accepted in the automation industry, provides an intuitive environment for new MT users

- An extensive debugging tool allows the monitoring and forcing of variables, thus making it easier to test the written programme directly on the device as well as with the help of the simulator

- A visualisation tool allows the creation of screens showing the state of the process in the form of animations, graphics, tables and graphs with the possibility of setting control values.

- Documentation tool

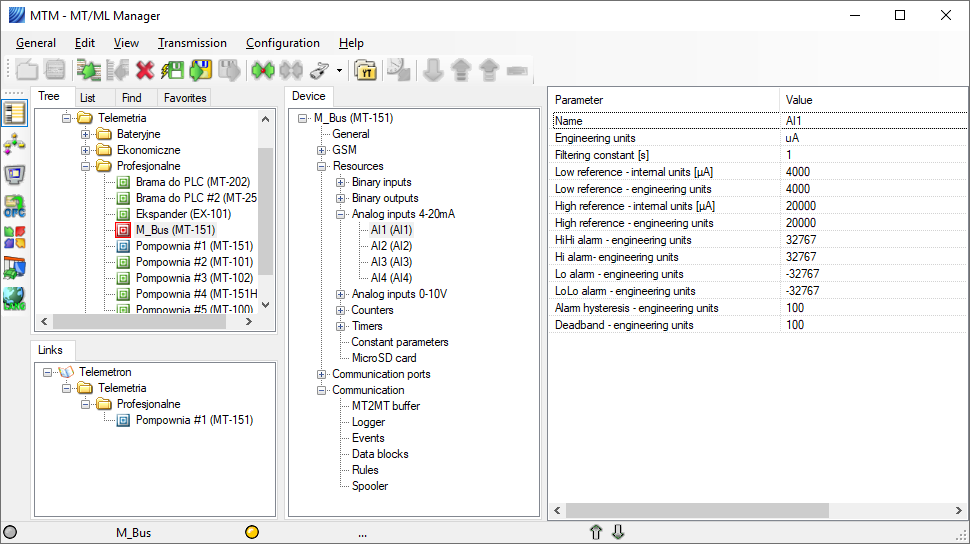

MT Manager (MTM)

Along with the telemetry and location tracking modules we deliver MT Manager (MTM) intuitive software tool for easy configuration of all parameters, operation modes and functions of each module, and for creation of the control program to be executed by the module. The user can freely name the modules and their inputs and outputs to ease the identification. The MT Manager does not require any specialised knowledge, and the meaning of particular fields and functions is clearly described in the documentation delivered in electronic and printed form.

MTManager – configuration

MTManager – configuration

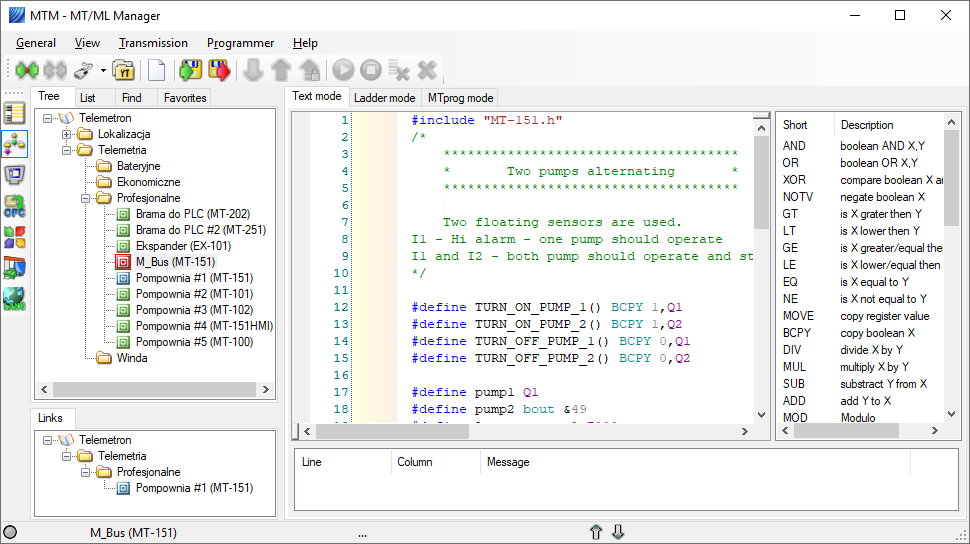

MTManager – text programming

MTManager – text programming

All changes of the configuration and control programs, including firmware updates, can be done remotely via GPRS network. Such capability saves time and reduces number of user trips to remote objects where the modules are installed. The built-in security system provides for each module the access password, and the lists of authorized IP addresses and phone numbers allowed to communicate with the module.

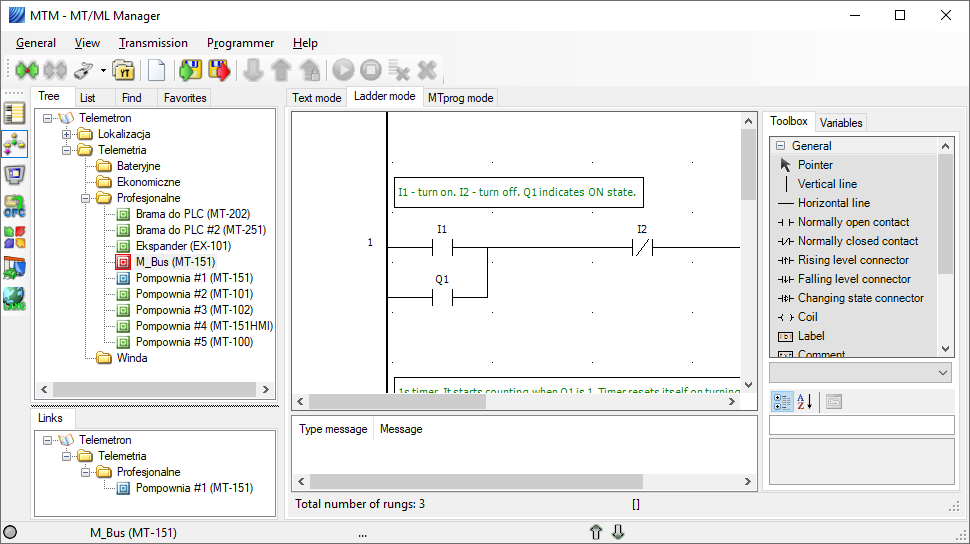

MTMmanager – ladder programming

MTMmanager – ladder programming

All attempts of non-authorised access to the module are ignored. In case of battery powered modules where the GPRS modem is inactive for most of operation time, the remote configuration changes are performed by the additional software package MT Spooler (MTS). The MTS queues the user defined tasks for each module in the system and sends them to the modules during the next connection session.

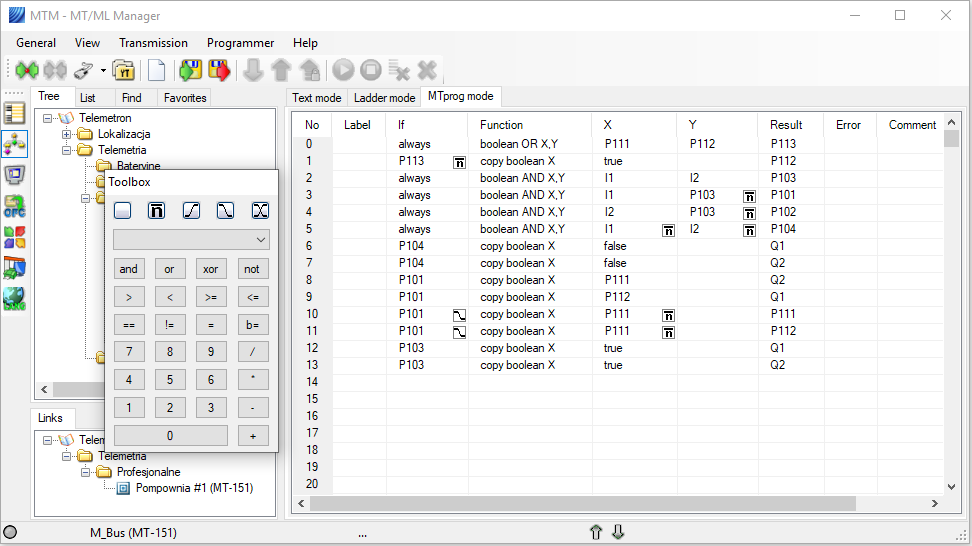

MTManager – MTprog programming

MTManager – MTprog programming

Additionally, we deliver free of charge communication driver MT Data Provider which supports the communication with remote telemetry modules using either MT gateway, GPRS modem or router, or Internet.

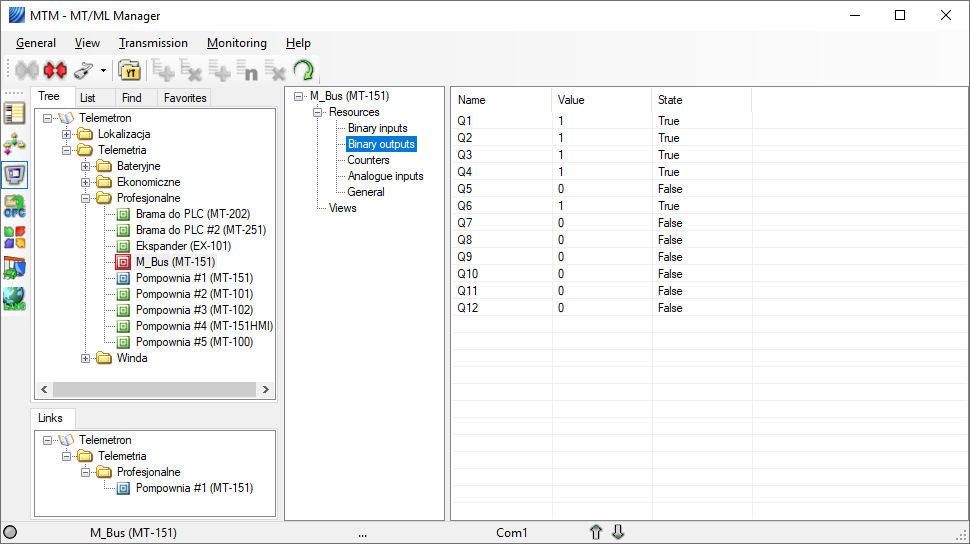

MTManager – monitoring

MTManager – monitoring

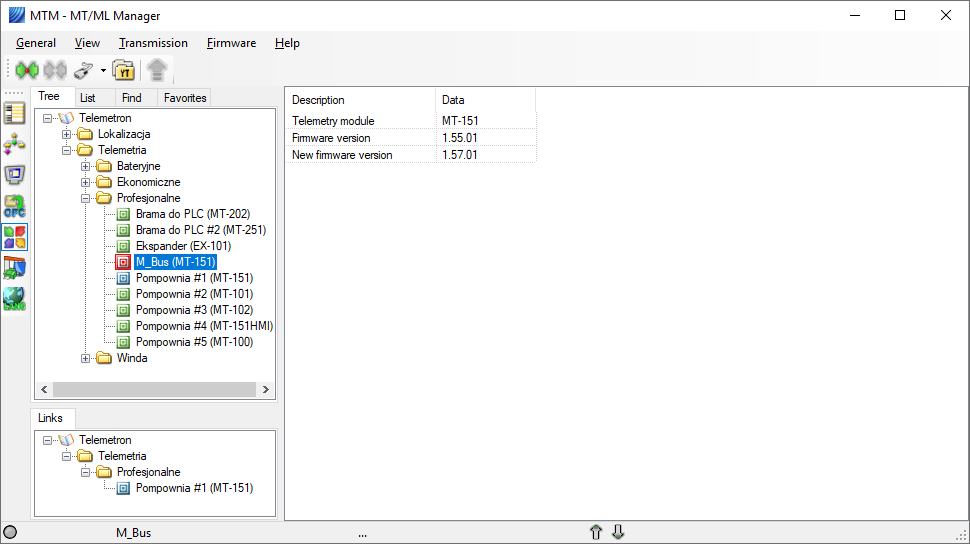

MTManager – firmware update

MTManager – firmware update

This driver works on 2000/XP/2003/2008/VISTA/7 platform and makes the current data accessible via standard OPC (OLE for Process Control) interface. All types of data (polled, event triggered, time-stamped logger records) are accessible in the form of CVS/XML files or can be automatically written to any standard relational database (e.g. MS SQL Server, MSDE, Oracle) via ODBC mechanism.

MTManager – firmware update

MTManager – firmware update

Such solution ensures open connectivity and easy integration with modern HMI/SCADA visualisation systems (animated graphics, trends, alarms), spreadsheets and data processing systems (billing, analysing, diagnostic and optimising systems).

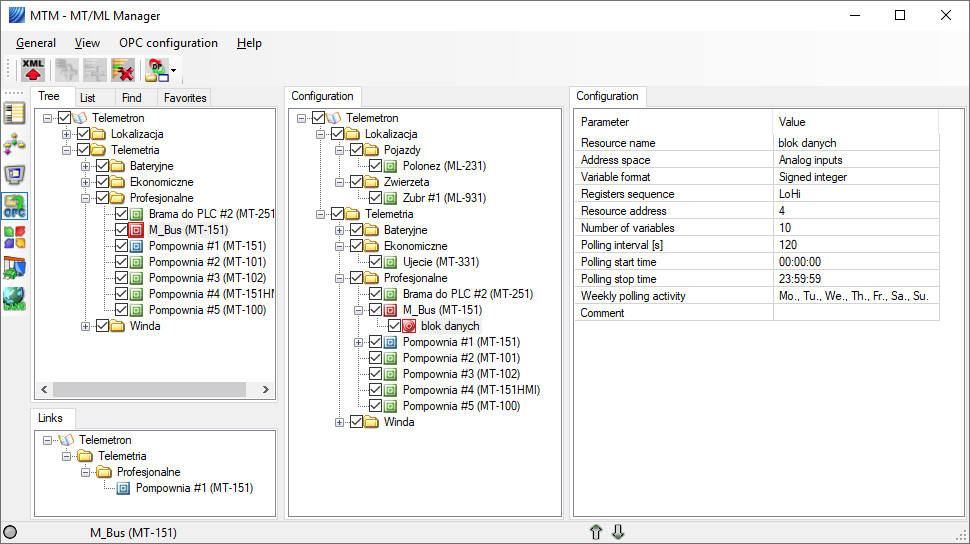

MT Data Provider - communication driver

The user also receives a free of charge communication driver called MT Data Provider that supports communication with remote telemetry modules via the MT communication gateway (e.g. MT-202, MTX-2050), GPRS modem, GPRS router or the Internet. The driver running on the Windows platform provides real-time data via the standard OPC (OLE for Process Control) interface, and historical data (logger records) via CSV/XML files. It is also possible to directly save measurement data via the ODBC interface to a standard relational database (e.g. MS SQL Server, MSDE, Oracle). This solution provides direct connection to modern visualization systems SCADA (animated synoptics, charts, alarms), spreadsheets and data processing systems (billing, analytical, diagnostic, optimization systems). Depending on the configuration settings independent for each telemetry module, MT Data Provider can communicate by polling the module at a specified time and/or accepting unsolicited event frames sent spontaneously by the telemetry module (unsolicited messages).

Using MT Data Provider brings the following benefits:

- Possibility of event-based operation of the system

- Carrying out tasks according to schedule

- Possibility to use data logger feature of telemetry units

- Ability to read data on demand

- Broadcast operation mode

- Open OPC/CSV/XML/ODBC data exchange standards

- Possibility of remote synchronization of RTC clocks in modules

- Support for all MT/MTX/ML series modules