Dedicated telemetry modules in cathodic protection

Introduction

Cathodic protection (CP) is an electrochemical method of corrosion protection that can be applied to any steel objects / structures buried in the ground or submerged in water. Cathodic protection is referred to as active protection, as opposed to passive ones, such as e.g. insulation coatings. Using simultaneously the active and passive methods provides effective and economical protection of the structure, resulting in failure-free operation over many years.

The principle of cathodic protection is to supply electrical current of sufficient density to the protected structure to produce the desired electrochemical effect. In case of low current demand the cathodic protection can be accomplished with the use of galvanic anodes. When the amount of electric current needed to protect the structure is significant (due to its large size and / or poor condition of the insulation coating), the so called impressed current system with DC power source (often a transformer-rectifier) is the most appropriate.

Cathodic protection is also associated with the problem of stray currents, which can cause corrosion of metals. One of the sources of stray currents is railway traction, and the factor contributing to their occurrence is the discontinuity of the rails forming part of the return circuit of the locomotive powering. Stray currents are especially dangerous for pipelines because they can flow in pipes at distances up to several tens of kilometers, and in places of their outflows they are capable to cause wall perforations in a very short time. One way to protect against stray currents is to install electrical drainages that are designed to drain stray currents from the structure to their source in a safe and controlled manner.

Since cathodic protection transformer-rectifiers and drainage devices are distributed over a large area and are often located in places difficult to access, it is economically justified to use telemetry to remotely control them and monitor their operating parameters.

Implementation

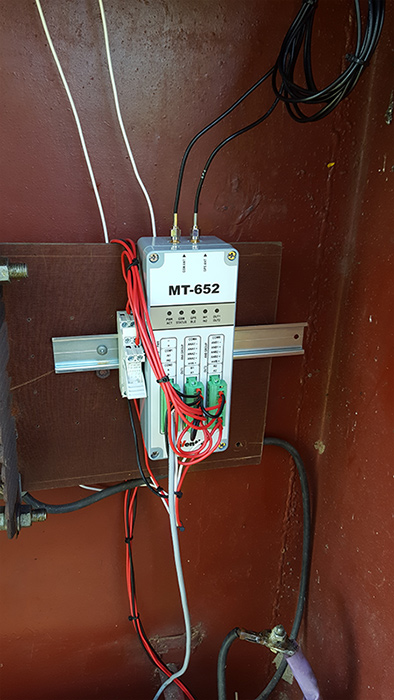

As part of this implementation, MT-652 modules have been installed in existing transformer-rectifier and drainage cabinets. The Customer, Gas Transmission Operator Gaz-System SA, has appointed 126 sites to launch a telemetry system in the operation area of regional units: Kraków, Pogórska Wola, Sandomierz, Jarosław and Jasło. The selected facilities include mainly transformer-rectifiers, as well as several drainage devices.

Since the existing facilities were built at different times and according to inconsistent standards, the installation of telemetry modules in each of them required an individual approach. Typically, the installation was done on a TS35 rail located on the right side of the cabinet. The following components were installed along with the telemetry module on the rail located in the transformer-rectifier cabinets: telemetry module power supply, measuring shunt and external relay selected according to the current rating of the CP power source. In addition, to enable the signalling of opening the cabinet doors, magnetic reed switches were mounted.

In order to ensure the ability to measure the IR free potential, coupons with an area of 10 cm2 used to simulate a defect were also installed at the drainage devices. Polarized drainage devices are not connected to mains power, so external battery packs were used to power the telemetry modules on these sites. The MT-652’s energy-efficient mode of operation allows maintenancefree operation in such conditions extending from several months to several years depending on the configured measurement frequency and transmission to the master system.

The installed telemetry modules allow the remote reading of operating parameters of cathodic protection devices, e.g. voltage and current output and ON/OFF potential at the drainage connection point. The devices also enable the remote switching of transformer-rectifiers and synchronous timing necessary for measurements. Synchronous measurement of IR free potential is also performed on coupons mounted at the drainage devices.

The devices have been fitted with SIM cards provided by the customer and incorporated into the TelWinSCADA software-based telemetry system used by the customer