Telemetric Modules in Control System applications

Utilizing the advanced functionality of the new generation MT-151, MT-251 and MT-331 telemetry modules from InVentia in applications developed and implemented by Control System – edition 02’2017.

Introduction

Dear Readers of TELEMETRON magazine, we are giving you the next article describing the most interesting solutions implemented by the engineers from CONTROL SYSTEM. Traditionally, this edition of the article is a follow-up of TELEMETRON magazine’s publications from 2008 to 2016.

In the 10th edition of the article, as in previous years, we would like to introduce to TELEMETRON readers the most interesting and technologically advanced implementations made in 2016, together with partner companies and made by experienced engineering team of CONTROL SYSTEM. Consistently, for years we have focused on delivering solutions that require expert knowledge and many years of experience, but at the same time remembering that our overriding goal is to create end-to-end applications of high quality which will fulfil the users’ expectations.

In 2016, all implementations made by our team were completely based on new generation modules, i.e. MT-151 LED and HMI, MT-251 and MT-331. The increased resources available in MT-151 together with the high performance of the modern processor used in this module significantly enhanced the functionality. The MT-251 3G gateway and WELOTEC routers provide seamless processing of data streams generated in networks consisting of over 120 telemetry modules. In many applications, the MT-331 module was used, which, due to its ability to work in two power modes, proved to be an extremely interesting device.

The closing balance of 2016 is already over 9500 pieces of MT-101, MT-151, MT-202, MT-251, MT-331 and MT-723 modules operating failure-free in Poland and Europe, with application software developed by CONTROL SYSTEM engineers.

In the following sections we will summarize the most interesting examples of telemetry modules applications.

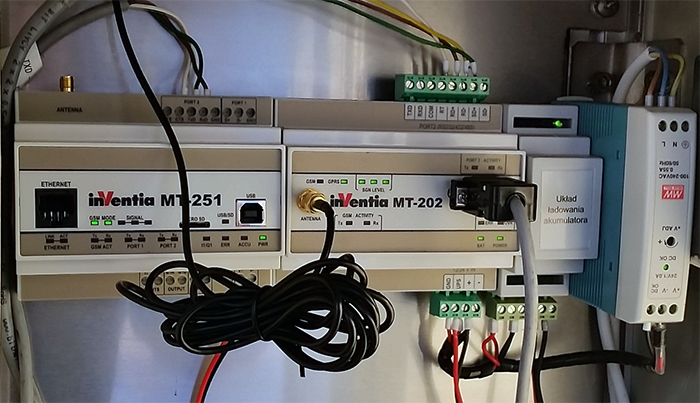

MT-251 3G module as a modern communication gateway and protocol converter for DCS systems

In 2016, at locations with more than 50 modules within a single telemetry infrastructure, MT-202 modular stations were upgraded to MT-251 3G modules at the dispatching stations, providing significantly higher data throughput to SCADA systems. The ability to connect the MT-251 to a local Ethernet network also allows the most effective selection of the module location, i.e. the location where GSM signal strength is the highest. The limitations associated with the use of the RS-232 standard have thus been corrected. The digital output available in the MT-251 module is used to control external optical / acoustic signaling and to effectively inform the operator about the need to check the status of the monitored object in the SCADA system.

Another interesting application of the MT-251 module was its use as a RS-232 to RS-485 and ETHERNET converter. In deployed applications, the MT-251 module reads data from the MT-101 module via the RS-232 port, which acts as a non-standard protocol converter from the measuring device, and then makes it available in the MT-251 registers after adequate processing. As a result, the user accesses data on port n1 (RS-485) in the form of ModBus RTU protocol or on ETHERNET port in the form of ModBus TCP protocol.

The solution described above was used in power plant to provide digital data from a specialized flow meter to the global DCS system.

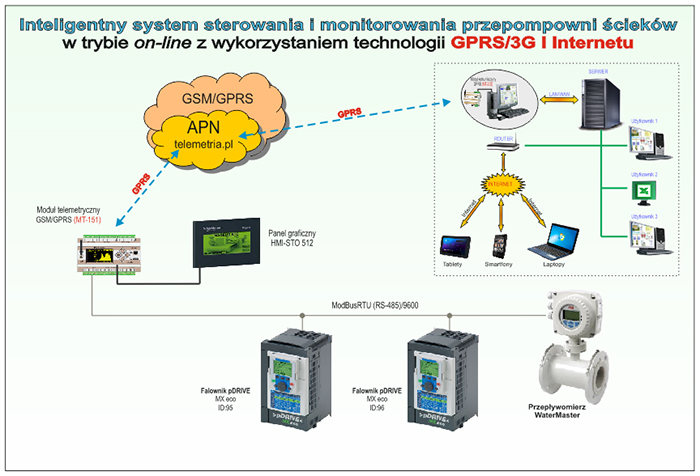

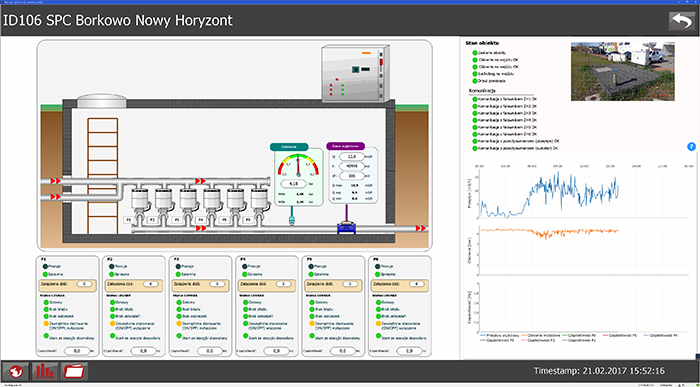

MT-151 HMI version mounted in control cabinets for sewage pumping stations

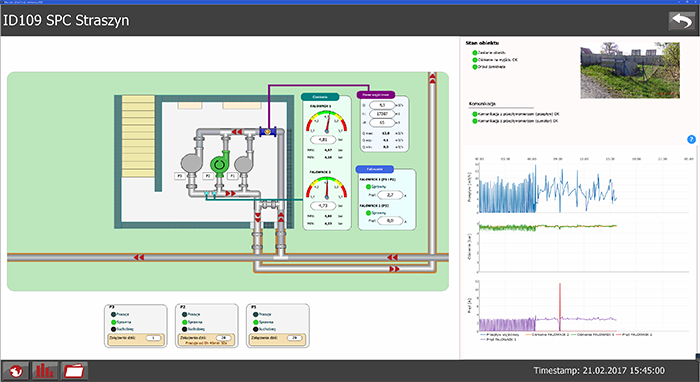

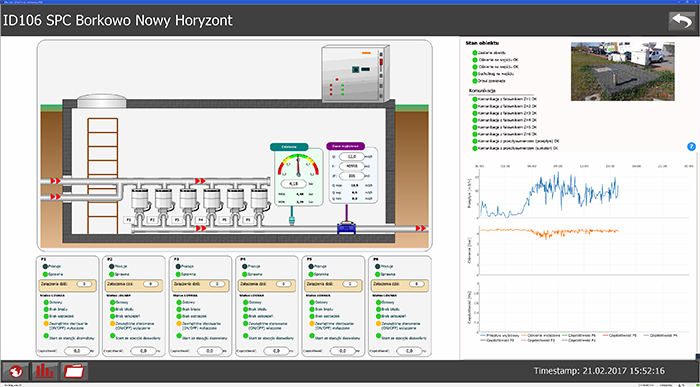

In 2016 our software team continued to develop application software to control the sewage pumping stations with the MT-151 LED and HMI modules. Application software has been designed to work with peripherals, such as inverters, soft starters, electromagnetic flow meters, network parameter analyzers, etc.

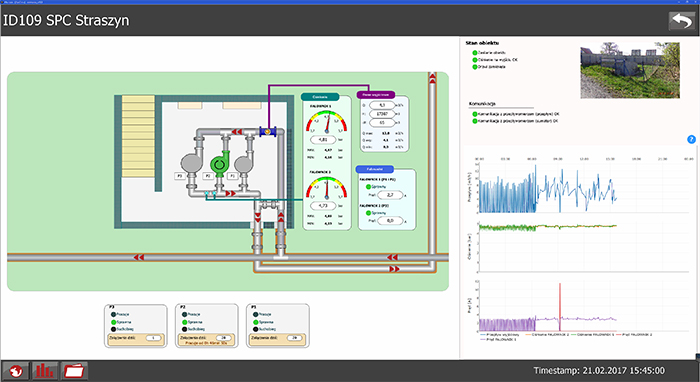

Available in the HMI version, the integrated graphics display provides local support for visualizing the most important process parameters without the need for an external graphics panel, estimated few hundred PLNs. Thanks to the extended resources of the MT-151 module, e.g. in the case of sewage pumps, it was possible to implement in one control module the operation of a drainage pump as well as an additional ventilator for the dry chamber. The possibility of connecting external temperature transducers to the MT-151 module allows for more precise controlling of the set temperature. The extension of functions implemented by the MT-151 module minimizes the number of additional elements in the cabinet. As a result, the use of the MT-151 does not increase the price of the control cabinet, but ensures that additional equipment is controlled by the application software stored in the MT-151 and all required additional information is transferred to the master SCADA system. The screenshot above shows an example of the control of a large sewage pump station equipped with a pressure transducer and an electromagnetic flowmeter.

In 2016, we made another increase in the number of features available in a unique graphics recorder, which is an essential component of SCADA system offered by CONTROL SYSTEM for visualizing pumping stations.

MT-151 HMI module controlling dampers in measuring chambers of clean water pipes

The functional capabilities offered by the MT-151 module are sufficient for the implementation of the complex mathematical process of controlling the valves in the control and measurement chambers of clean water pipes. In this case, the MT-151 software receives data from several measuring points, equipped with flowmeters and pressure transducers and, based on a complex algorithm, controls the angle of the throttle to maintain the desired flow of water in each segment of the water supply.

Below there is an example of a visualization of two chambers.

The examples presented here demonstrate the functional capabilities offered by the MT-151 telemetry module, which in such cases successfully replaces the traditional PLC connected to a GSM modem. Integration of process control and data transmission (3G) in one module and the ability to remotely modify a program in the MT-151 significantly reduces the costs associated with launching an object.

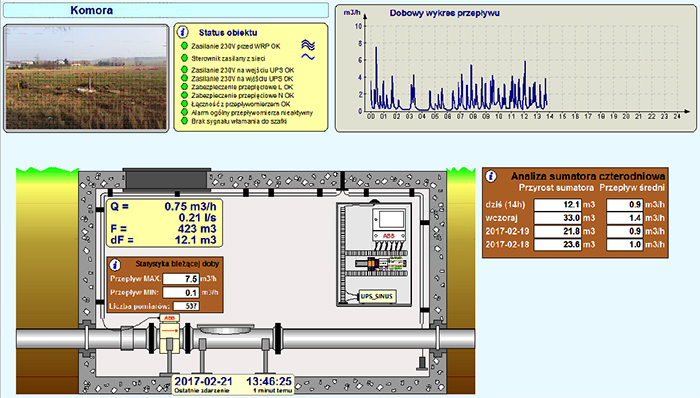

Metering of sewage flow using ABB flowmeters and MT-101, MT-202, MT-151 modules

In 2016, together with ABB, the monitoring of flowmeters installed for billing purposes was continued. Offering the ABB flowmeter in a packet along with a monitoring system, which is additionally equipped with dedicated modules to verify the accuracy of the indications and generate balance sheets, minimizes the possibility of conflict in relationships between sewage donor and recipient.

In the first picture below an example of monitoring the sewage flow on a sewer collector connecting two municipalities is shown. Data from the flowmeter is read by the MT-101 telemetry module using digital protocol, then sent to the database server and shared to both parties.

On the second screenshot below there is an example of a flow monitor in a measuring chamber equipped with an ABB flowmeter (PROCESS MASTER model), a HART2ModBus RTU protocol converter, and an MT-101 module. Due to billing purposes, the power supply and telemetry cabinet is equipped with a UPS.

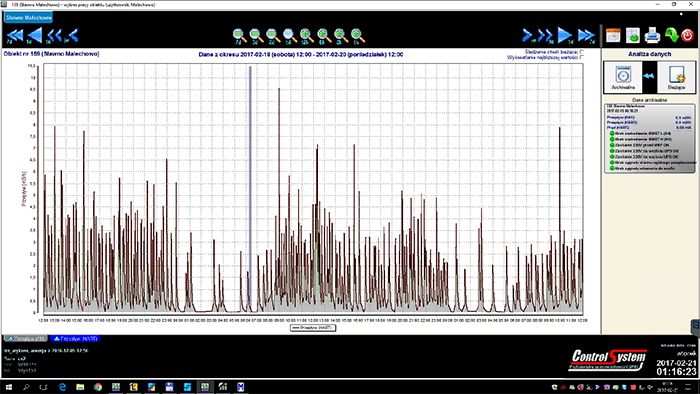

Measurement of sewage flow on transit pipes using ABB flowmeter, MT-202 and MT-151 modules

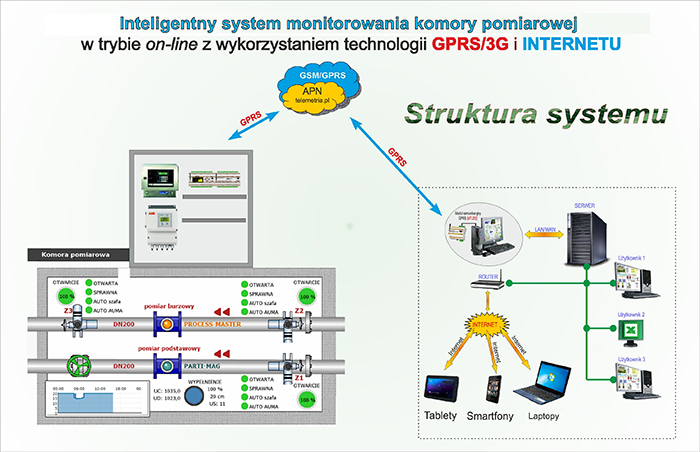

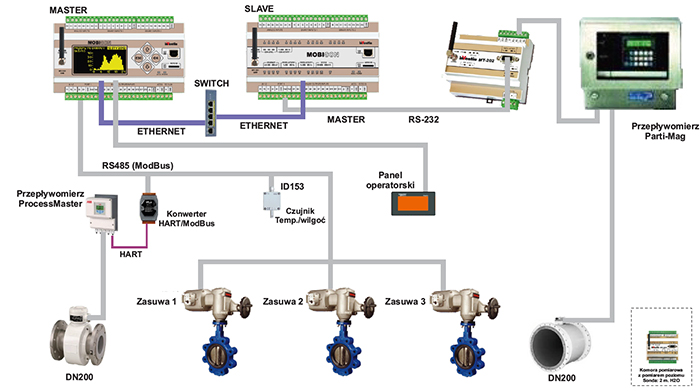

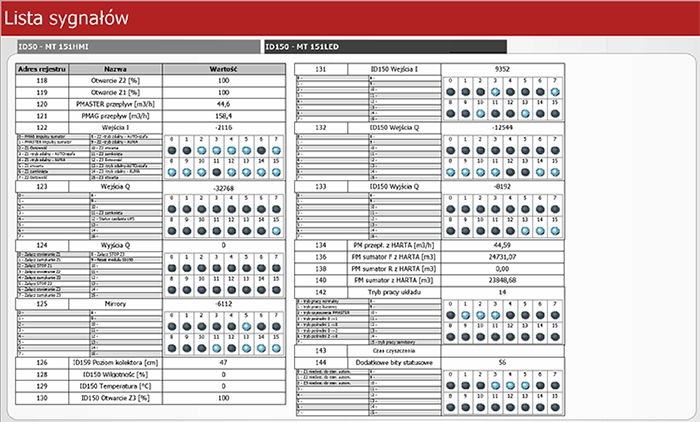

Measurement of sewage flow, especially in cross-site settlements, requires the use of precision measurement systems, consisting of accurate and professional measuring equipment and a remote monitoring system to control the measurement process. In 2016, CONTROL SYSTEM engineers have implemented an advanced system for measuring sewage flow in the transit pipes. Due to ABB’s specialized flowmeters and the designed hydraulic system, it has been necessary to implement extensive flow analysis and gate control in the system to ensure the possible highest accuracy of the measurements. Due to the complexity of the control system, the number of signals forced the use of two MT-151 modules. In order to improve the data exchange reliability, the MT-151 modules are additionally connected to each other with the ETHERNET bus.

Dedicated applications for MT-151 modules have been developed for control of the measurement process. Each module performs a part of the process, and data between modules is exchanged over the Ethernet bus and additionally are using redundantly the wireless GPRS technology.

The diagram above illustrates the communication capabilities offered by MT-151 telemetric modules.

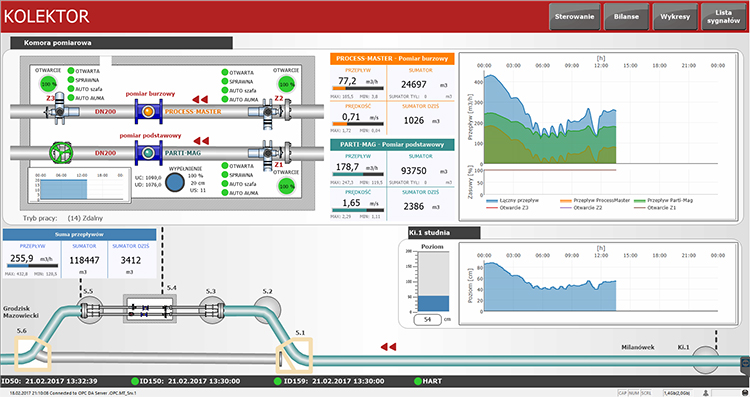

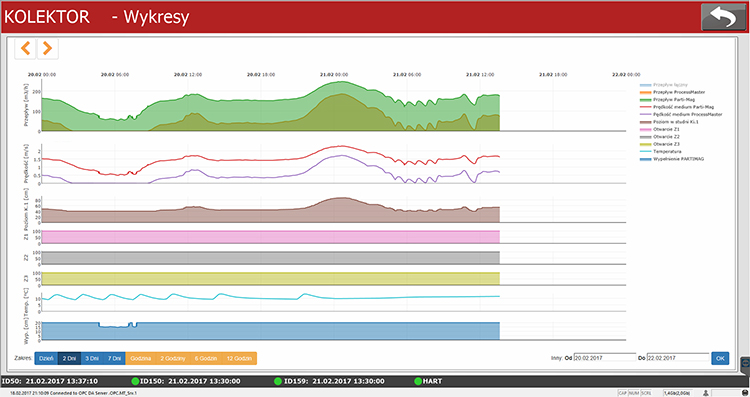

The measurement process has been visualized in a dedicated application created in the Movicon SCADA environment by PROGEA. Below the screenshot from the visualization system is shown.

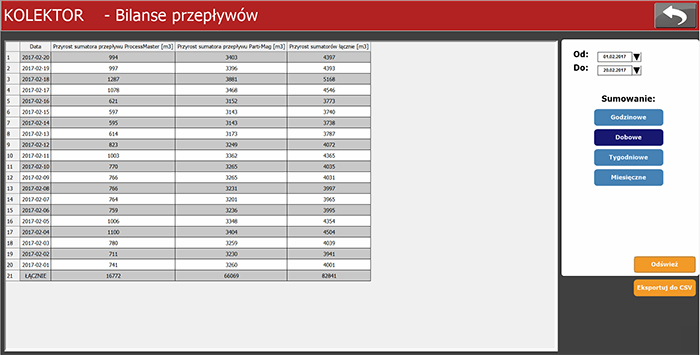

Detailed flow charts.

User-specific hourly, daily, weekly, monthly, annual, or operator-defined balances.

In the described visualization application created in SCADA system, the so called dashboards are used to present the substantial data for the user.

MT-331 telemetry module for tank monitoring applications, powered by renewable energy sources

Metering the targets, such as clean water tanks, due to the distance from the low voltage power lines, does not have a 230 V supply voltage and requires battery powered modules or the use of renewable energy sources to supply metering and telemetry equipment. An interesting example is the picturesque reservoir in Zubrzyce area.

The water level in this tank must be maintained in the upper zone to ensure continuity of water supply to residents. Information on the current water level should be sent to the MT-151 module installed on a remote pumping station, where two pumps pumping water to the reservoir in Zubrzyce. Until August 2016 data transmission was performed by the MT-713 module. The water level measurement cycle took place every 10 minutes. Measurement results were collected in an internal logger of the module, which “wakes up” at every full hour and sends the contents of the buffer to the SCADA system.

The drawback of this solution was the need for periodic battery replacement in the module, which created many problems due to the nuisance of access to the facility, especially during the winter. The board of the company decided to install a photovoltaic panel and to replace the MT-713 module by the MT-331. A special telemetry cabinet with two batteries adopted to use with photovoltaic panel, MPPT regulator and MT-331 module was manufactured.

The result was absolutely satisfactory. The MT-331 module normally operates without power saving mode. Level measurements are made every 5 minutes and sent to the SCADA system and to the MT-151 module in the water pumping station. For two months critical because of the insufficient sunshine, i.e. December and January, there was once no battery discharge to a critical level, causing the receiver to cut off.

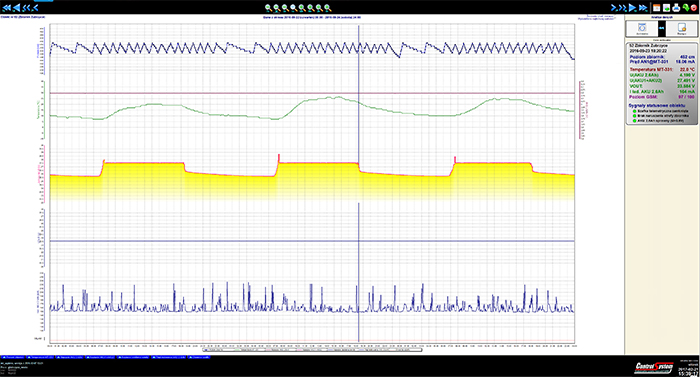

Below are charts showing the course of changes in monitored parameters.

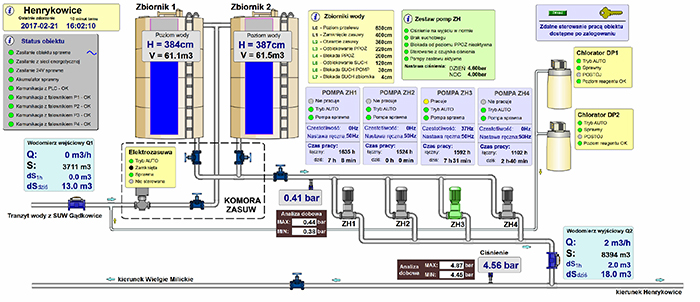

Monitoring of hydrophore sets equipped with their own PLCs using the MT-151 telemetry module

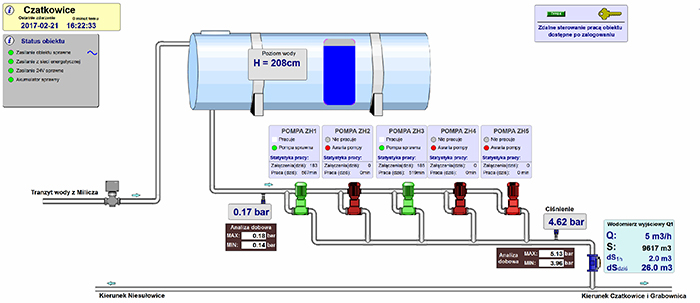

In 2016 a relatively large number of objects included in the visualization system were hydrophore sets. In many applications, CONTROL SYSTEM has incorporated the objects of various equipment levels into the visualization systems. In this area of application, the MT-151 modules have proved to be excellent. Due to the availability of RS-485 and ETHERNET communication ports, in most cases it was possible to successfully create a digital connection with PLC controllers and to transmit data using ModBus RTU or ModBus TCP protocols. On the next page there are examples of visualization made with the Movicon SCADA system.

The ETHERNET port is also used in some applications to connect the MT-151 module to the graphics panels.

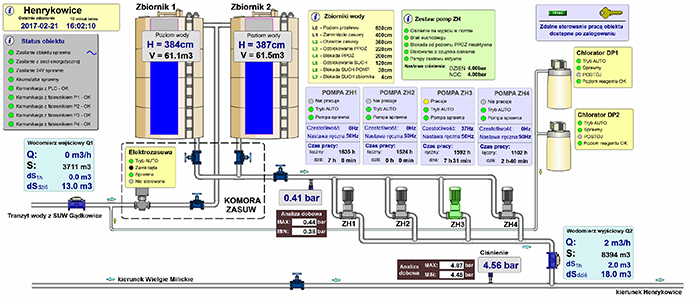

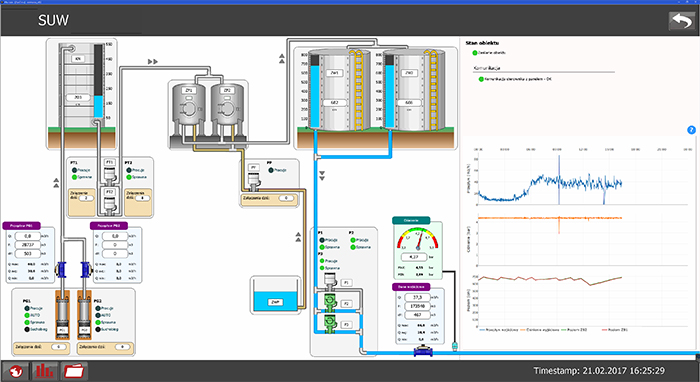

Monitoring water treatment plant

Controlling of small water treatment plants (WTP) based on the MT-151 module is a very cost effective and efficient solution. The ability to remotely debug a control program without entering the facility is a significant reduction in the cost of running a process control. Availability of the ETHERNET port allows you to enable the MT-151 module in your local network and transfer data to the SCADA system without the use of GPRS technology.

For larger stations, the water treatment process is controlled by PLCs that are connected by a digital bus to the MT-151.

Below is an example of a visualization of a water treatment plant operating in the municipality of Milicz.

On subsequent screenshots, examples of visualization of further WTPs are shown.

Below is shown the dashboard created in Movicon SCADA system, which readily presents the operator with a summary of the most important parameters of monitored objects and alarm information.

Below is shown the dashboard created in Movicon SCADA system, which readily presents the operator with a summary of the most important parameters of monitored objects and alarm information.

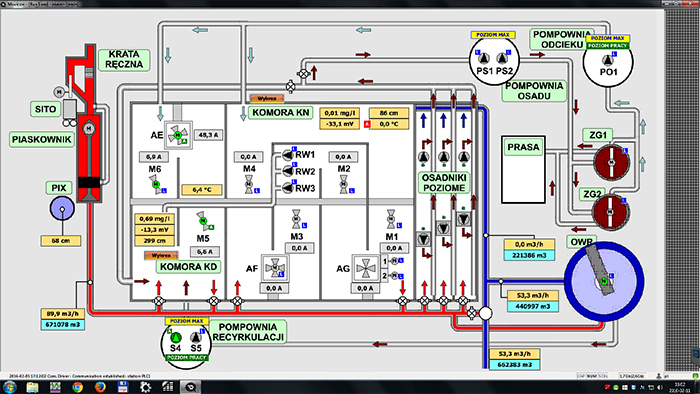

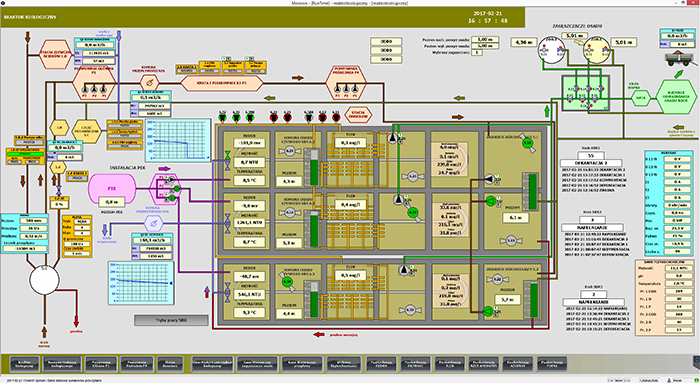

Visualization of the sewage treatment plant made in the Movicon SCADA system by Progea

In 2016, the visualization systems of sewage treatment plants were developed using the Movicon environment distributed by AB-MICRO.

Screenshots above show the examples of visualization of several sewage treatment plants implemented in the Movicon 11.4 SCADA system.

Summary

Summary

The year 2016 is a decisive dominance of the MT-151 and MT-251 modules in applications implemented by our engineering team. The functionality of these modules has been consistently developed over the past years allowing the complex control systems implementation. By implementing the new applications, we did not experience any constraints, and in particularly demanding cases, we have combined two MT-151 modules, resulting in a two-processor structure.

Virtually all new implementations of visualization systems have been implemented using Progea Movicon SCADA system, distributed by AB-MICRO. Our engineers have greatly appreciated the opportunities offered by Movicon and its openness to modifications that allow you to personalize your applications to your expectations. To conclude, the technological level of products offered by Inventia combined with the capabilities of the Movicon SCADA system allow our team to safely meet the next challenges in 2017.